SERVICES

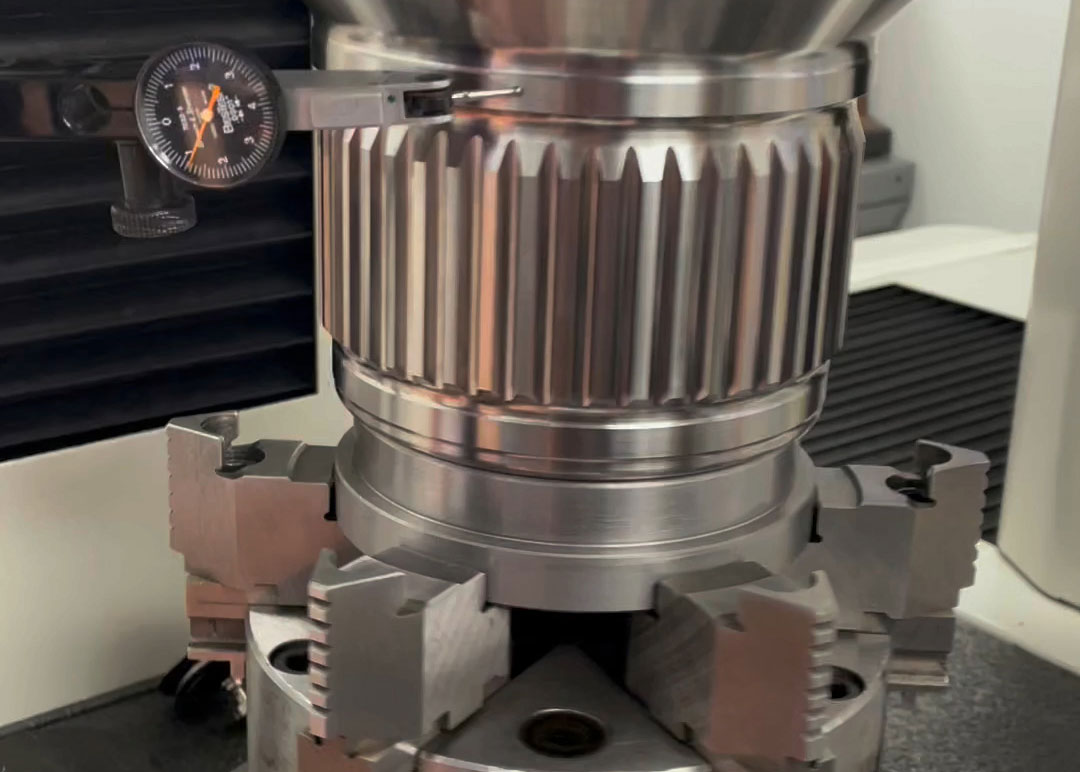

United Gear & Machine Company works with the top space, defense and aerospace companies to produce precision splines and gears. From ground support tooling to flight safety engine components, United Gear & Machine has the machinery, expertise and attention to detail to perfectly execute your next project.

GEAR & SPLINE CAPABILITIES

Below is a list of our base capabilities. Please feel free to contact us to learn more about our services and have us provide a custom plan for your gear and spline needs.

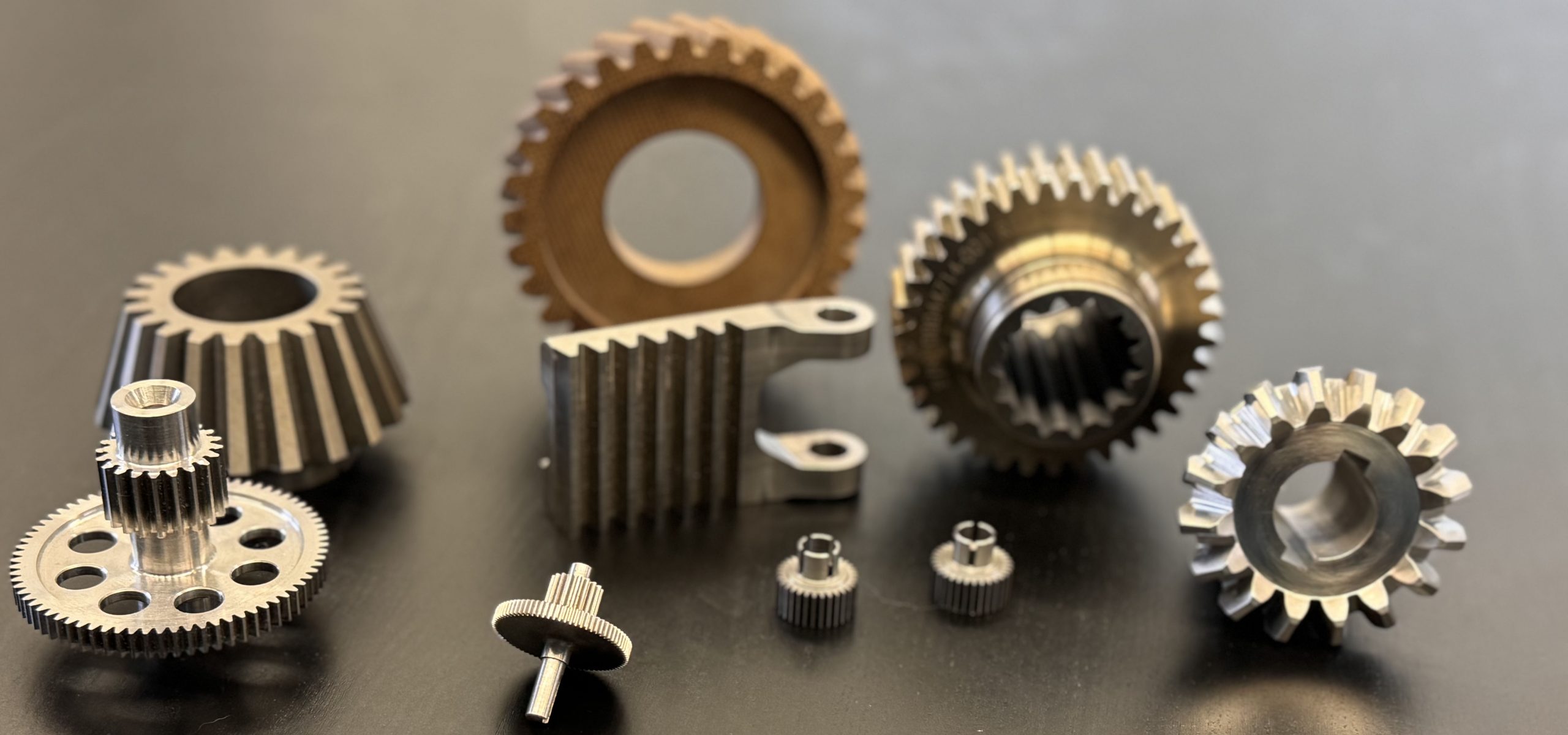

Spur Gears & External Spline

120 D.P. to 1.25 D.P.

Up to 48″ DIA.

Metric Gears – All Modules

Internal Splines

Fine Pitch to 4 D.P.

Up to 7″ Face

Gear Crowning

We can crown external gears to reduce noise and vibration during use.

Broaching

Involute Splines

Keyways, ‘D’ Hole

Hex, Double ‘D’

Involute Serrations 45°

Worms

64 D.P. to 6 D.P.

Worm Gears

64 D.P. to 2 D.P.

48″ DIA. MAX.

Racks

22″ Length

Up to 6 Pitch

Face Gears

96 D.P. to 10 D.P.

Up to 6″ DIA.

Bevel/Mitre Gears

Straight Bevels up to 12″ OD

Please contact us

Gear Grinding

CNC Grinding of external spur gears

.5 (50 pitch) to 10 Mod (2.54 Pitch)

Sprockets/Timing Belt Pulleys

All Types

Please contact us

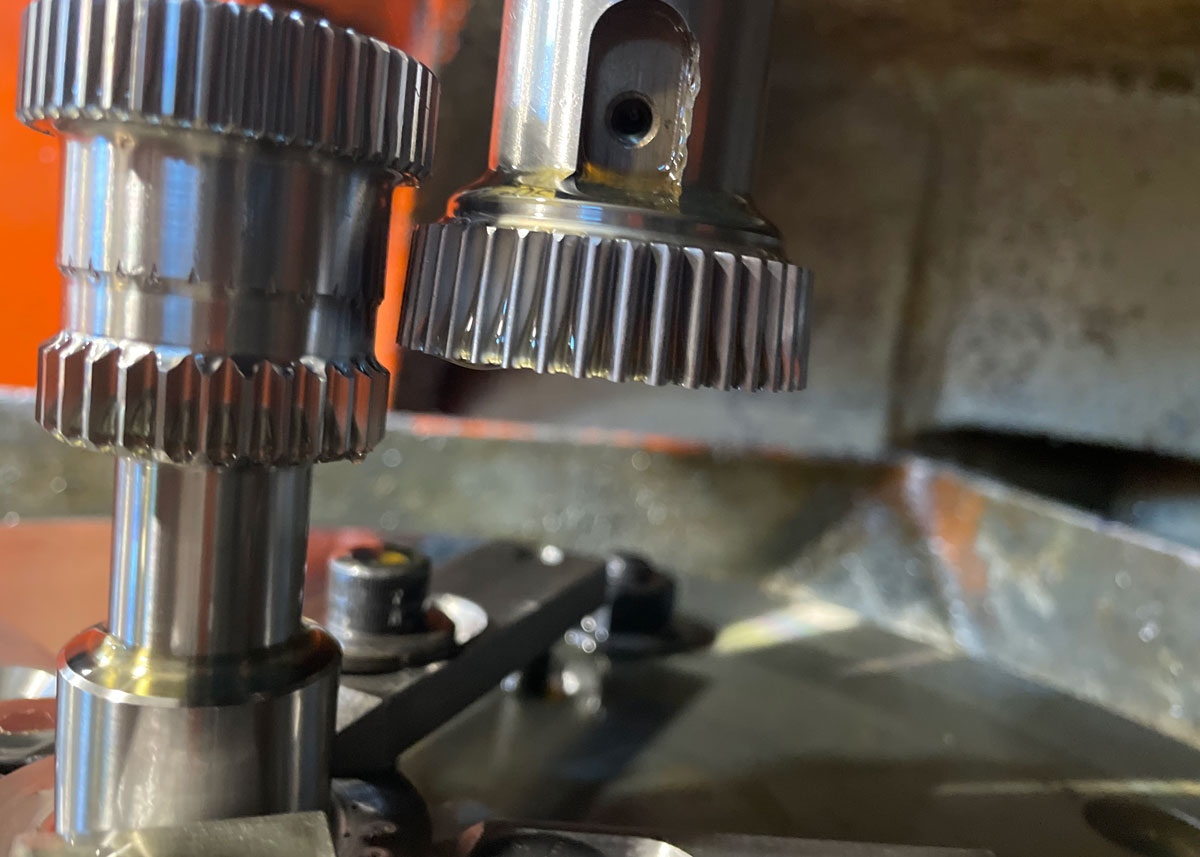

Helical Gears

96 D.P. to 3 D.P.

Internal and External

Please contact us

Keyways

Broached to 5/8″ Wide

Blind Keyways up to 9″ OAL

Shaped to your specifications

TURNKEY ORDER MANAGEMENT

Our Turnkey Purchase Order management is a robust and dynamic system led by the experienced Operations Manager, John Jackopsic. Operational improvement is a key focus, driven by the dedicated Engineering Team.

A notable aspect of our Turnkey Purchase Order management is the well-established network of AS9100 & NADCAP Approved Vendors. Machining, Heat Treating, Non-Destructive Testing (NDT), and Coatings are all conveniently located within an hour, ensuring quick and reliable access to essential services. This strategic network enhances our ability to deliver high-quality products on time and within specifications.

Our Turnkey Purchase Order management is characterized by robust project management, consistent revenue growth, operational excellence through procedural implementations, and a well-equipped and connected Engineering Team. The strategic network of approved vendors further positions us as a reliable and efficient partner in delivering top-notch products and services.

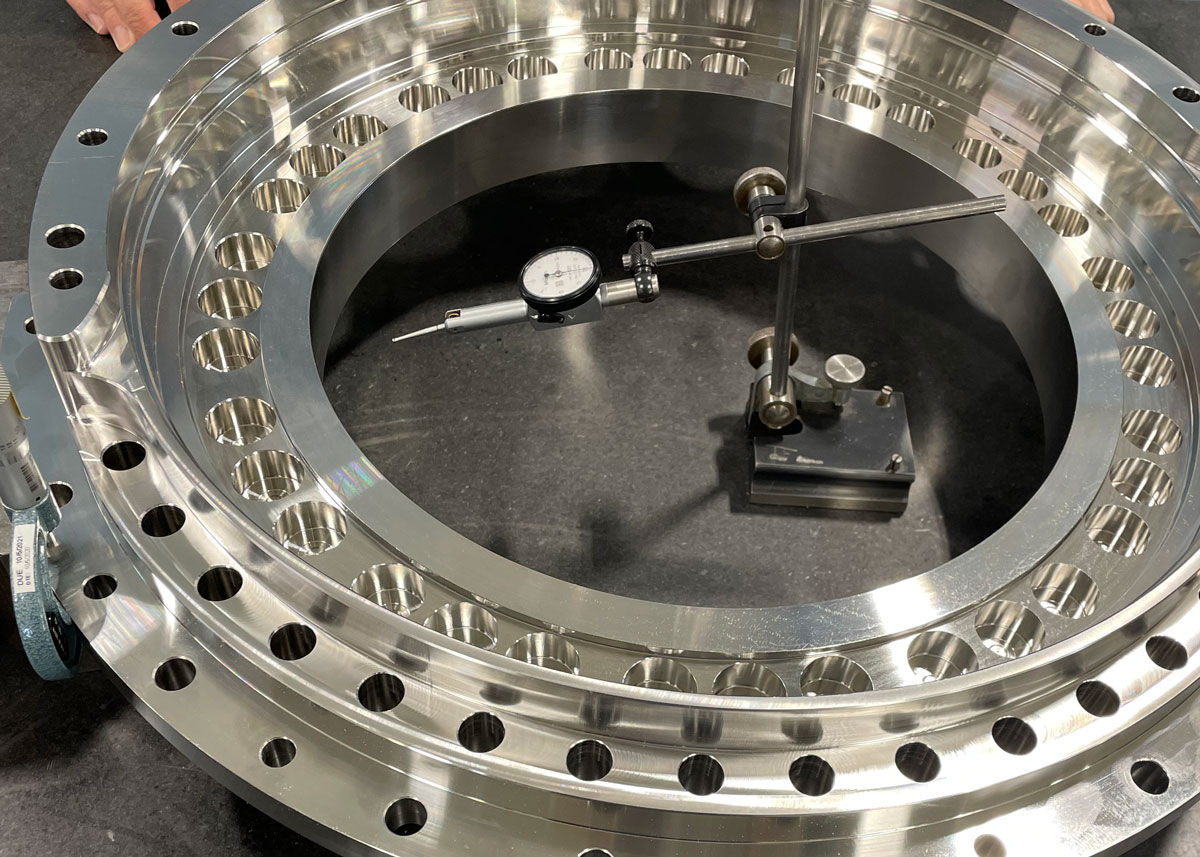

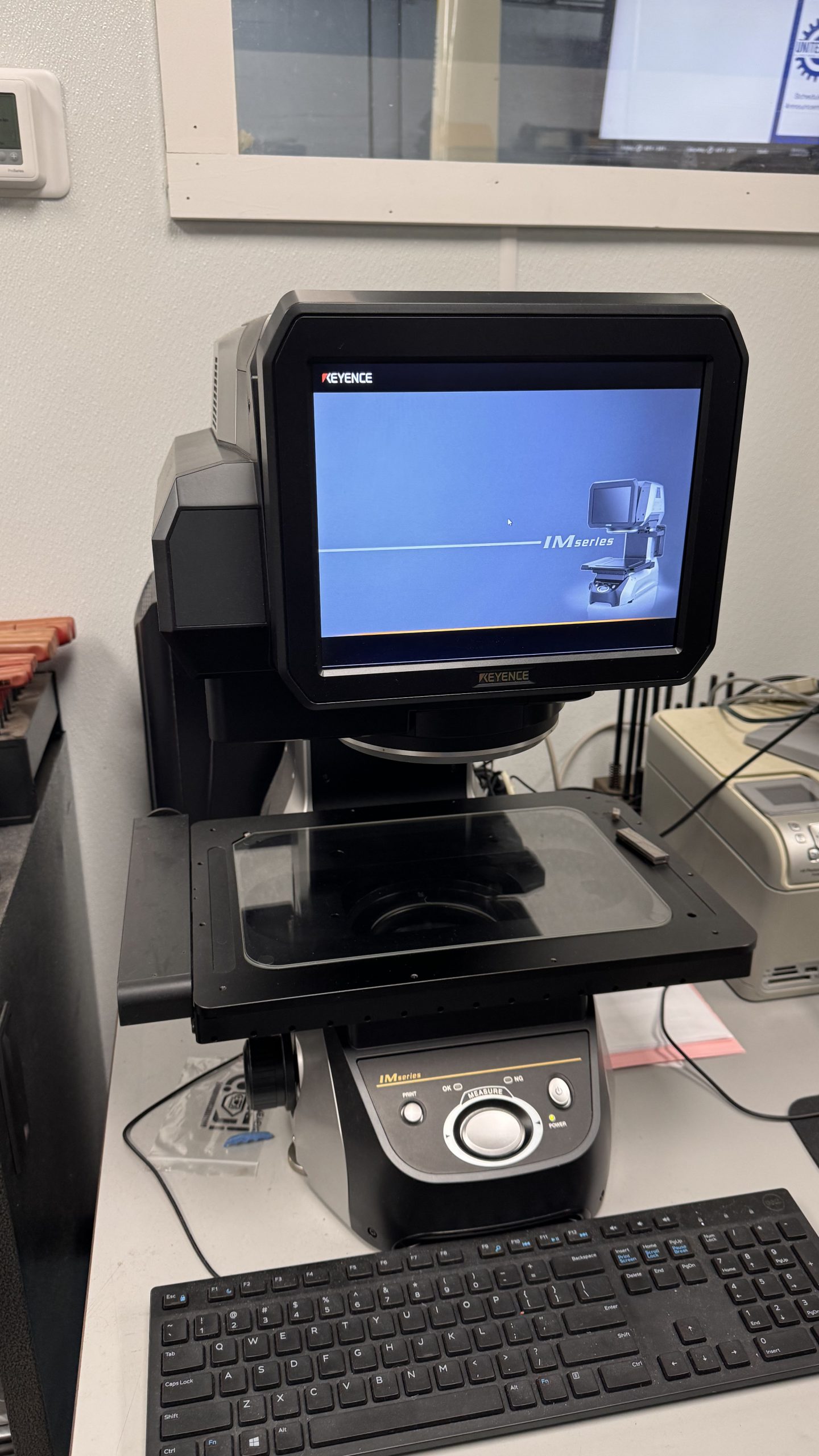

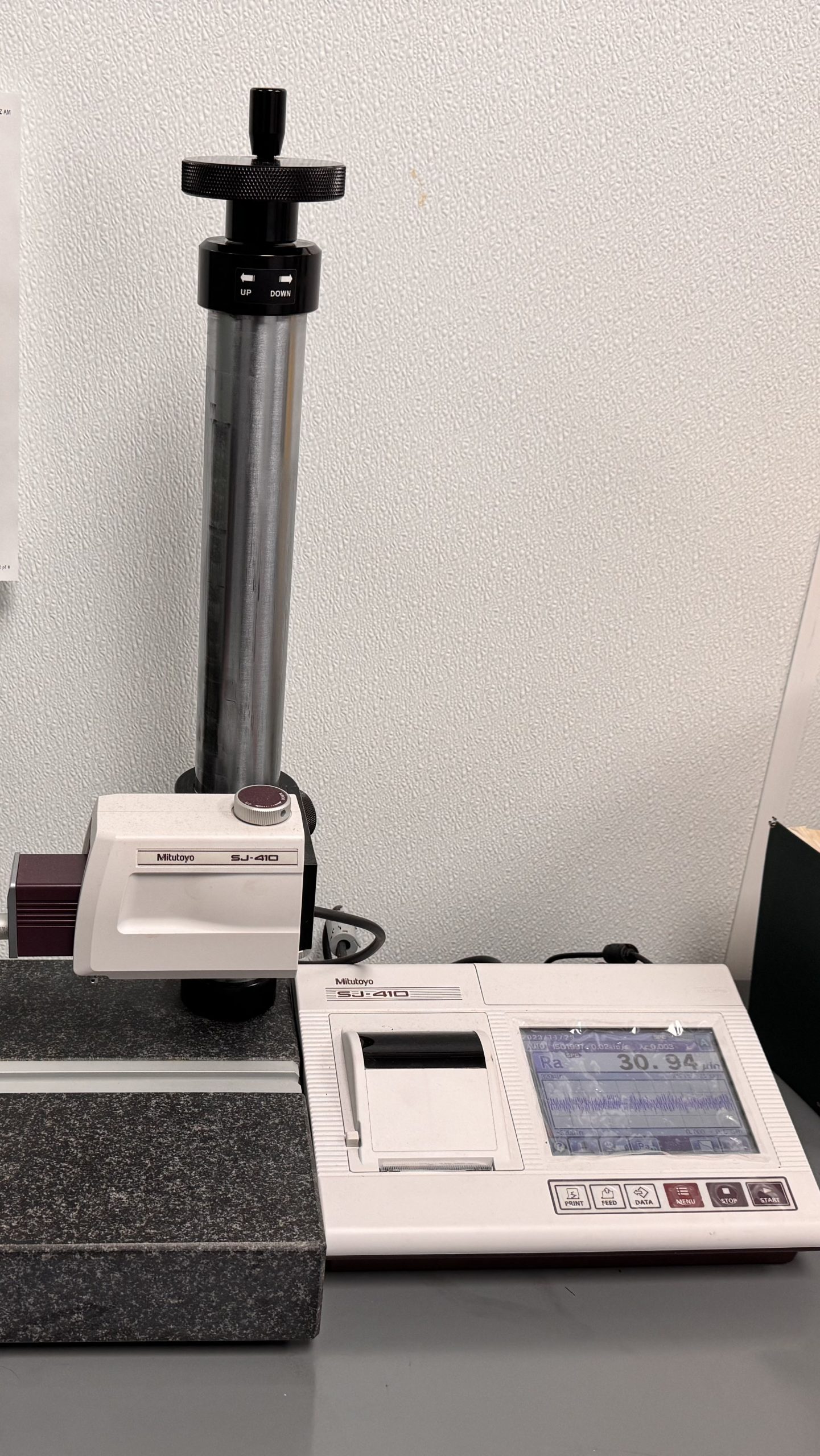

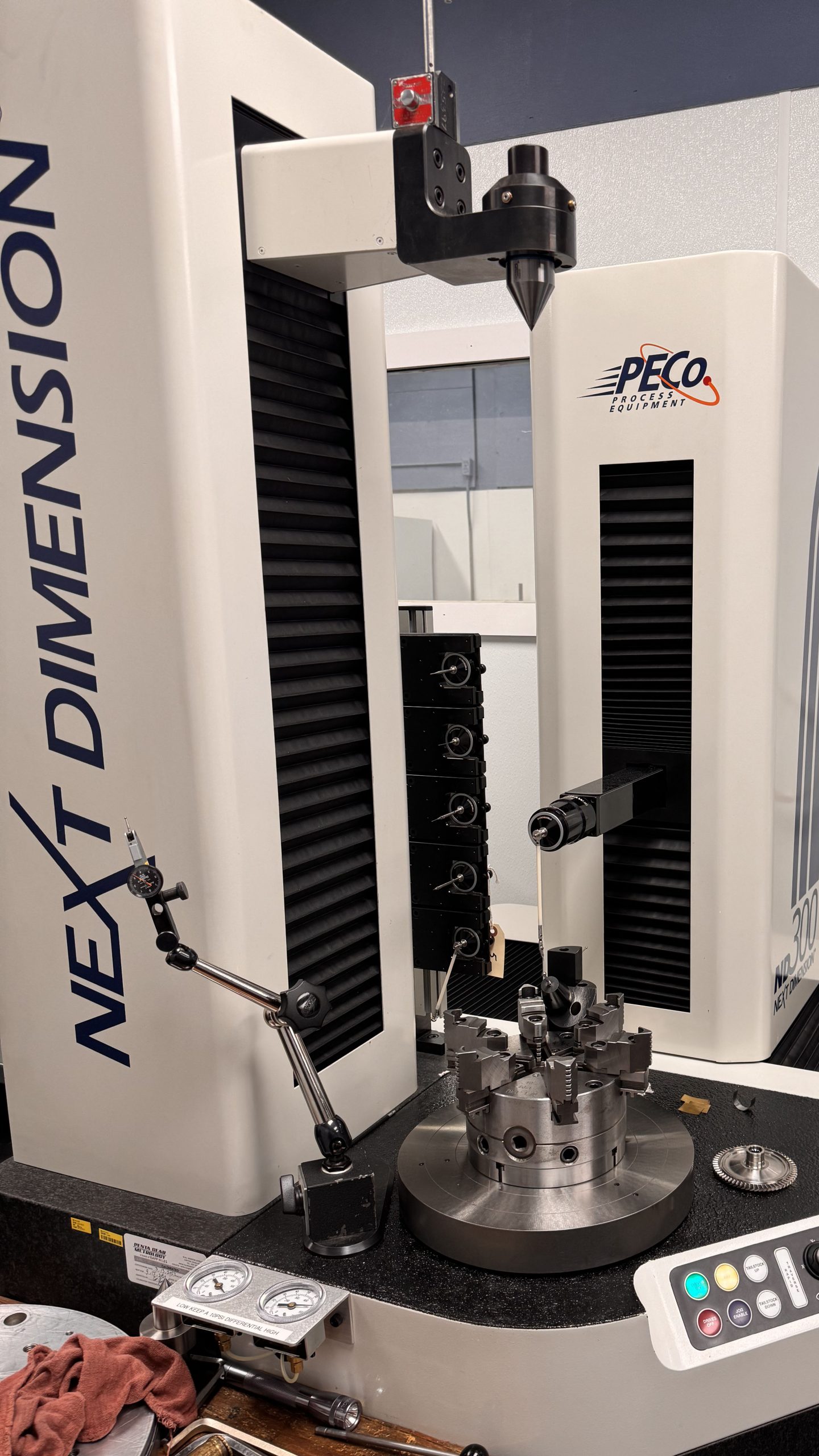

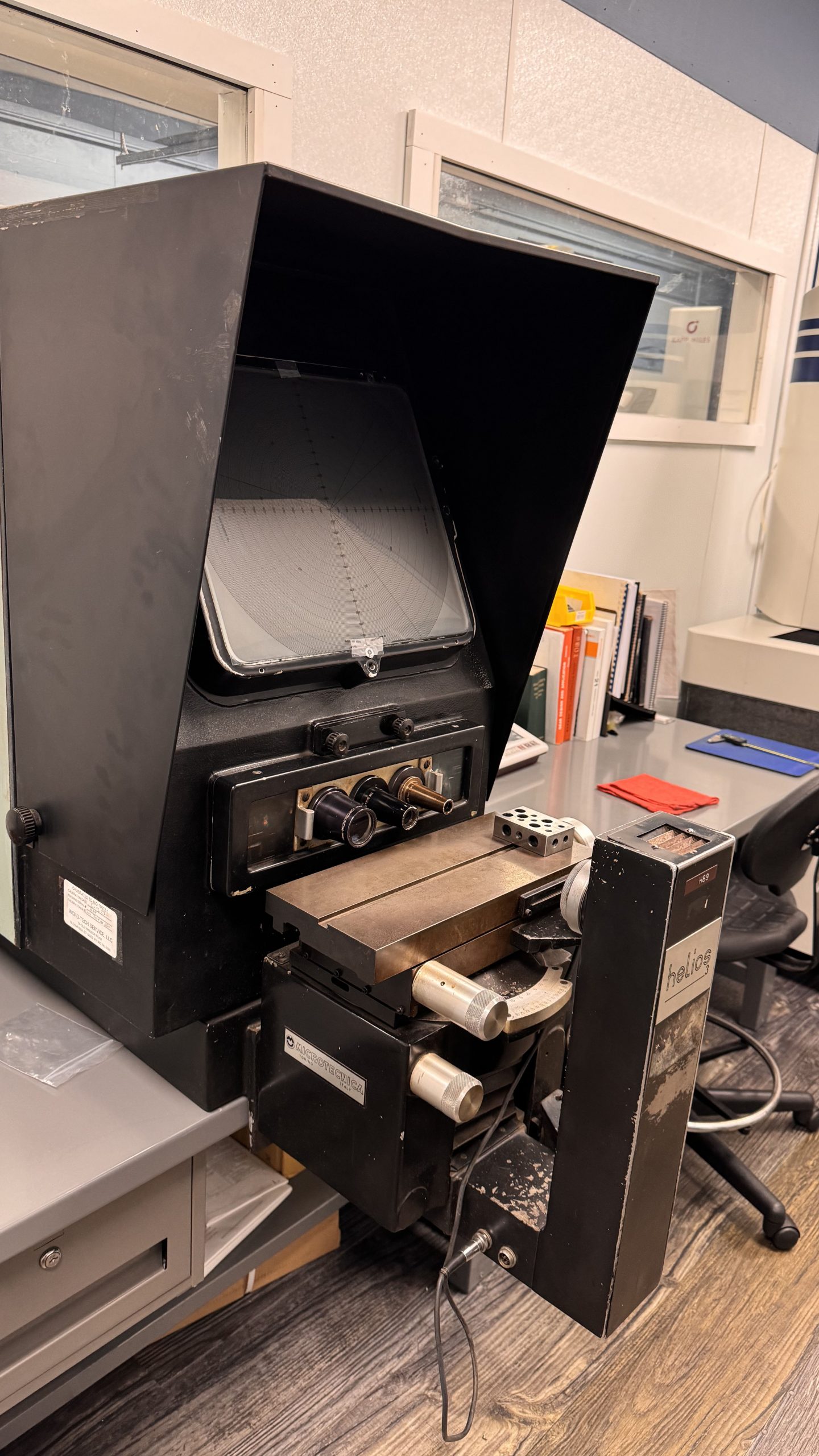

INSPECTION SERVICES

We know that gears can be confusing. Let us help!

Whether it’s a legacy part you need help reverse engineering, or a spline cut somewhere else that needs verification, United Gear’s experienced team offers dimensional inspection, quality consulting, and third party verification services for your gears and splines.

DEBURRING SERVICES

WHY CHOOSE US?

For the past 70 years, UGM has been a leader in spline and gear manufacturing. Many of our employees bring over 30 years of industry expertise to every project in order to provide excellent customer service. In fact, we have been serving many of the same happy customers for over 60 years.

United Gear invests in its employees, making sure everyone has the newest, most relevant skills. We provide on the job training, partner with local trade schools and work with machinery OEMs to ensure all our employees have access to the latest trends and technology as well as the tired and true methods of aerospace manufacturing.

We ensure that the quality of of work meets with the highest customer standards. United Gear & Machine has been ISO 9001 and AS9100 Certified since 2014. We hold several prime approvals, including Bell Helicopter, Blue Origin and other industry leaders is space and aerospace.

We take customer privacy importantly and ensure that we adhere to strict cyber security policies following NIST 800-171 requirements and are an ITAR registered facility.

We are driven toward excellence and work to continually improve our manufacturing procedures with one thing in mind: customer satisfaction. We have streamlined our manufacturing processes with the use of the latest technology and our goal is simple: create the best quality, most affordable parts for our Customers. We offer creative thinking and solutions to all your machining needs. The strong relationships between our company, customers, and suppliers is immediately evident when you work with United Gear. We treat every job, despite the size, with the same amount of attention to detail and eye for quality. We work with the client to deliver competitive pricing and will work to meet even the most aggressive project timelines.

FREE QUOTE

From one piece to thousands, let us quote your next gear and spline project.